To minimize the general loud and rattling background noise of a cargo van, we will put up noise insulation in our Sprinter in the course of the van conversion.

If you ever drove a cargo van, maybe when you were moving or bought some bulky furniture, you know it is usually much louder in such a van than in your regular car. Most of the noise doesn’t come from the engine though. The vibration of the engine rather sets the metal of the bodywork in motion – and that generates the typical noise.

So before applying the thermal insulation you should consider noise insulation; just think about it and inform yourself because different people have different opinions on this. We decided to use noise insulation!

Widely established for noise insulation is Alubutyl, which is made of one layer of aluminium and one layer of butyl rubber – hence the compound word Alubutyl. By applying Alubutyl, the metal of the bodywork is made thicker and heavier, therefore the metal is not set in motion as much, and that’s why it won’t be as loud. The net weight of the material itself is quite heavy though and makes the vehicle heavier. That’s why you should only apply Alubutyl where it’s necessary – on big surfaces. Just check by knocking: The higher the sound, the more the noise insulation is necessary on this particular spot but bars as well as spots with reinforced metal don’t need noise insulation.

Alubutyl is available in mats on rolls, in different thicknesses: 2 mm and 2,5 mm. We chose the thinner version. Just cut small panels with a craft-knife and apply these with a wallpaper seam roller (or rather its „frame“) and some pressure directly on the metal.

Attention! While researching cheap alternatives you might read about bitumen panels. We advise you not to use them! Bitumen is made of petroleum. When it heathens up, for example when the sun is shining and it’s hot, it starts to smell. And these smells might cause health issues. Don’t save in the wrong place.

Pros

- Good noise insulation

- Less background noise as well as less noise from the outside

- Easy processing by self-adhesive back

- Easy to cut with a craft-knife

- Not causing health issues

Cons

- Heavyweight

- Comparatively expensive

- Sharp edges; using working gloves is recommended

Price

- Thickness 2 mm: approx. 17,50 € / m²

- Thickness 2,5 mm: approx 23,00 € / m²

Alubutyl is available online here.

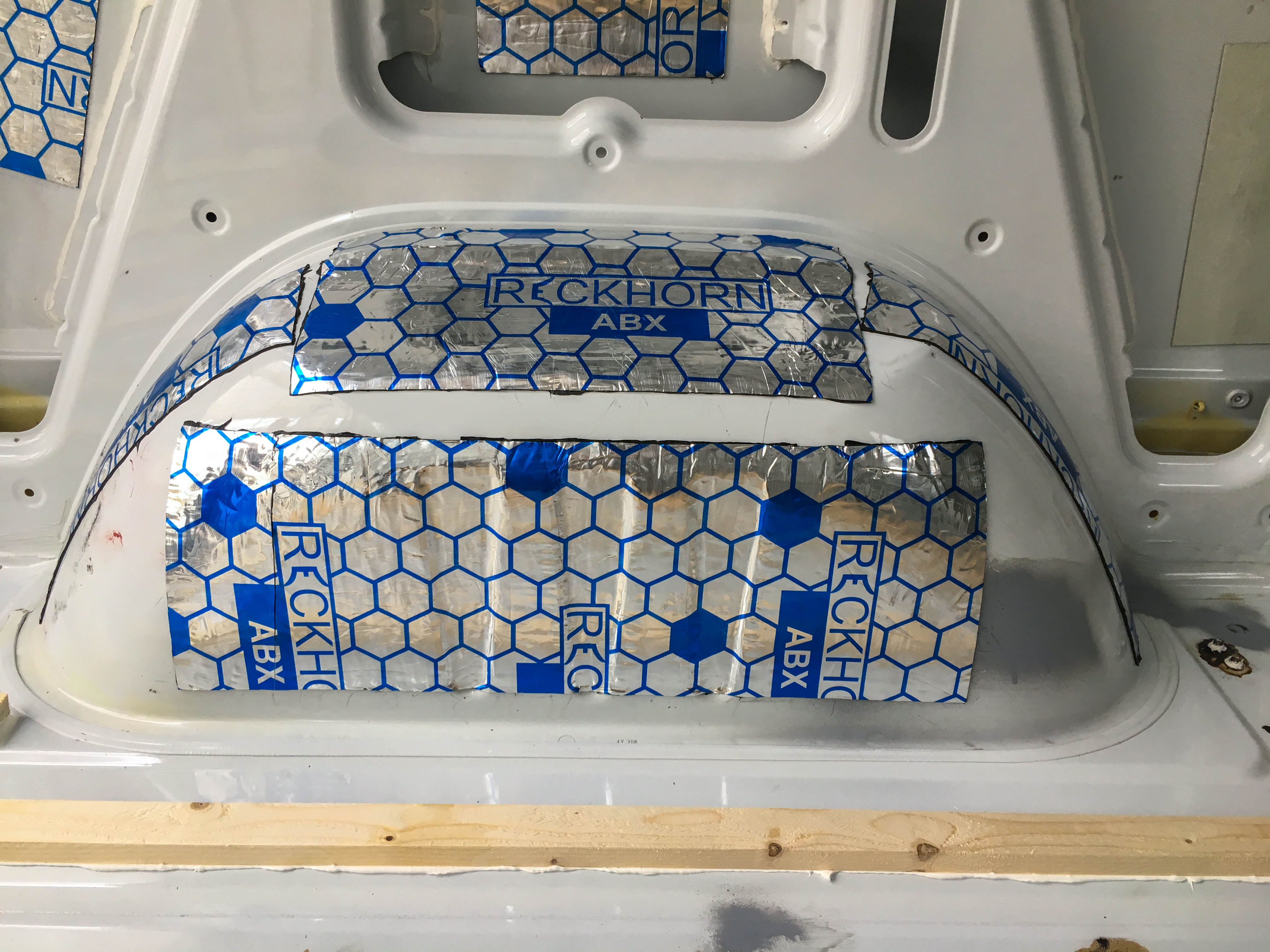

Alubutyl in practice

Yes, Alubutyl is quite heavy and yes, the edges of the aluminium are quite sharp so you should really wear working gloves at all times. The surfaces need to be dirt and grease free, Alubutyl is then applied directly on the metal. It is relatively easy to cut with a craft-knife. We recommend to put the side with the aluminium down (it’s just easier to cut) and use a hard and stable surface as a base because you need to apply some pressure to cut the material. For the application we got some wallpaper seam rollers, but put away the actual roll pretty soon and only worked with the frame to press the Alubutyl onto the metal; with lots of pressure. For the layer of aluminium mot to scratch the metal or the paint, we always made sure the butyl oozed out a little.

We mainly used Alubutyl on the wheelhouses and big surfaces of the side panels as well as narrow strips on the roof. In addition to this we put the noise insulation on the floor of the driver’s cab as well as on the roof beneath the car headliner.

Of course the thermal insulation will also reduce noise. We will find out how well the insulation with Alubutyl works as soon as we’ll hit the road with our Sprinter!

Read more about campervan insulation basics. Up next is thermal insulation with Armaflex-AF, pros & cons as well as information about price and availability and then there’s tips and alternatives to Armaflex-AF.

The following products were used for the installation: